Lowering Manufacturing Costs with Cobots–Collaborative Robots

According to Adobe’s 2018 Digital Intelligence Briefing, only 15% of businesses use some form of artificial intelligence today. However, over the next 12 months, Adobe predicts that 31% of companies to implement it. Companies are implementing robotics into their production lines in order to increase speed and differentiate themselves. This upward trend is foreshadowed to continue, meaning companies in the industrial industry need to stay on top of these trends to be able to compete with the competition.

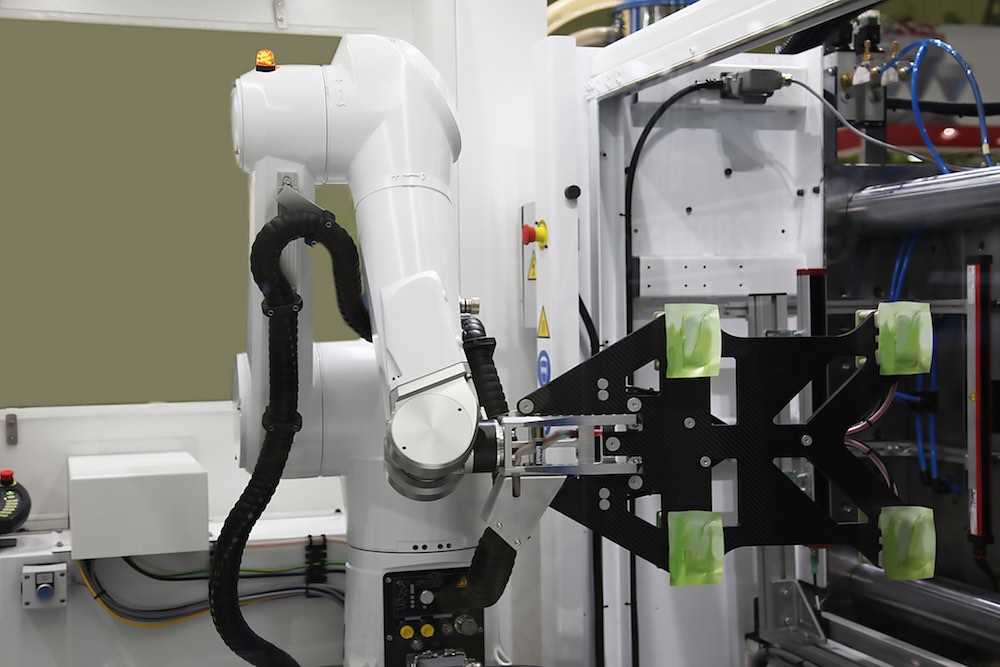

TechTank has recently begun working with Live Automation to implement collaborative robots for B2B companies in the industrial, automotive, and manufacturing industry. Collaborative robots assist in various processes including injection molding process, CNC machining, and more to provide a competitive edge for producing low-cost, fast, and high-quality products. Aside from selling customers collaborative robots, TechTank offers new product development and in-house services including CNC machining, injection molding, and cybersecurity. From product design to production, TechTank has the resources, staff, and processes to turn your product idea into a finished result.

Eliminate Errors & Reduce Expenses by Using Collaborative Robots

Businesses in the 21st century are highly competitive and falling behind leading competitors die to irreparable disasters. Although collaborative robots have only been commercially available for about a decade, they were actually invented back in the 90’s. Alongside modern industrial automation, terms like ‘Cobot’ are showing up in the web space more than ever. The most obvious benefit of purchasing a collaborative robot for manufacturing processes, aside from offering higher efficiency to industries, is freeing up floor space and lowering the cost of implementing non-collaborative robotics. For example, a non-collaborative robot used in an automated cell must be guarded to keep operators outside. The guarding itself can be expensive, especially when gates, interlocks, and interfacing to the cell controller are included. However, the cost of moving material in and out of the cell is often overlooked. With collaborative robots, the cage is eliminated and an operator can work alongside the robot, positioning the material or workpiece, and removing finished pieces as needed.

Less obviously, collaborative robots permit flexible manufacturing practices. Even when equipped with vision systems, there are limits to a robot’s ability to handle unexpected conditions. Consider a material removal cell where a robot is trimming plastic moldings. Excess material builds around the tool and workpiece and pushes the plastic away from the tool. In a collaborative setup, a human operator can step into the cell and the robot will pause while the buildup is removed. Then, with the operator safely out of the way, production will resume.

Collaborative robots can save space and money and increase flexibility. Live Automation requires all automated machines to meet strict safety guarding and safe operational requirements. Still, it is essential to conduct a formal risk assessment before ditching the cage.

How TechTank Uses Collaborative Robots for Industrial & Commercial Applications

TechTank uses collaborative robots for a wide range of tasks. Unlike standard robots, collaborative robots have numerous abilities, letting TechTank use them for their own custom needs. Collaborative robots perform people-oriented tasks, especially the mindless and tedious ones that do not involve a high amount of skill. Things such as stacking and unstacking heavy boxes, filling and emptying containers, and organizing materials are completed with the use of these collaborative robots. Implementing automated robotics over manually operated equipment eliminates repeated tasks that can result in a human error during any manufacturing process. TeckTank’s team of professionals can now focus on continuously supervising, administering, monitoring, and analyzing all machines and robotics more efficiently instead of working on the tedious actions involved in CNC machining, plastic injection molding, etc.

By replacing manually operated machines for specific tasks, TechTank has been able to create quality products with faster turnaround times. Live Automation’s collaborative robots can run nonstop for several months, reducing idle times and shortening long-term projects. Reducing the time spent on manufacturing services not only results in quicker turnovers, but it allows TechTank to take on more significant projects and manufacture massive quantities at once. Resources and time are no longer wasted, resulting in more revenue, setting TechTank apart from other CNC machining and injection molding companies.

TechTank’s Quality Low-Cost Manufacturing Services

TechTank offers a vast range of plastic injection molding services, working with all thermoplastic materials such as acrylic, PETG, and polyurethane. TechTank performs contract injection molding services for many industries including, industrial, medical, and retail. TechTank focuses on providing inexpensive prototyping to confidently compete with other plastic injection molding and CNC machining companies and their costs across the world.

Some types of injection molding services we offer include:

- Conventional injection molding

- Open/close, slide, and insert molding

- Two-shot/over-molding

- Small tonnage machines ranging from 22-150 ton machines

- Prototype services with 3D printing

- 3D printed prototype molds

- MUD frame inserts

- Overflow manufacturing

- Mold studies and tool analysis

Some CNC machining services we offer include:

- Electrical Discharge Machining

- Milling

- Grinding

- CNC Lathe

- Milling

- Grinding

- CNC Lathe

TechTank has the ability to provide all plastic injection molding services on full-sized runs but mainly works with small to medium sized runs(around 5,000 pieces). At TechTank, we do more than plastic injection molding and CNC machining. TechTank provides in-house new product design, development, prototyping, and manufacturing for various products across hundreds of industries. TechTank has the resources needed to take a new product idea from a concept and turn it into a reality, manufacturing high-quality products with quick turnarounds. Unlike your average machine shop, TechTank’s mission is to provide our customers with the best possible products inexpensively. For more information on the advantages of buying collaborative robots with TechTank, contact one of TechTank’s professionals today!

Recent Comments