by

Brock Allen

|

January 22, 2019

|

Blog

When deciding whether to use thermoset elastomers(rubber) in product design, manufacturers try to figure out what distinguishes rubber from plastic in the context of precision, molded parts. Product designers think a part design using thermoset elastomers are interchangeable with plastic; however, the chemical properties and molding characteristics of the two are very different. With applications requiring smaller parts and more difficult configurations(such as any pet toy, kitchen gadgets, or other consumers goods) new product designers must address all challenges that could arise in the development process.

At TechTank, our injection molding process provides reliable, high-quality, and cost-effective products. With our inexpensive prototyping and use of alternative materials, we have the chance to decrease any harmful toxins released into the atmosphere, TechTank can confidently compete with injection molding costs overseas across all industries.

Liquid Silicone Rubber(LSR) vs. Thermoplastic Elastomers(TPE)–Choosing the Right Material

Thermoplastic elastomers(TPE) and liquid silicone rubber(LSR) have similar characteristics and chemical properties. Both are ideal for many types of injection molding projects; however, there are some considerable differences manufacturers need to be aware of when deciding which material to use for specific end products. While TPE and LSR are useful alternatives to synthetic or natural rubber and may sound relatable, they are in fact not interchangeable. TPE material is a thermoplastic while LSR material is a thermoset. Each material provides different properties, behave inversely during the molding process, and contrast in their reaction to heat. For example, LSR hardens while TPE melts. Both TPE and LSR have similar physical characteristics at room temperature, but there are specific advantages and disadvantages of using TPE over LSR, and it’s vital to determine which is right for your application.

When comparing TPE vs. silicone(LSR), there are many benefits to using thermoplastic elastomers to construct pet toys, kitchen gadgets, and additional consumer good products. For instance, they use less energy during production. Thermoplastic elastomers are a blend of polymers that melt and form into plastic when heated. Manufacturers shape and fabricate TPE when temperatures reach its melting point then cool the plastic to harden the mold, without changing the chemistry from form-to-form. Having no chemical bond within thermoplastic elastomers, TPE is then pressure-molded into various components that strengthen and retain their shape during the curing process.

Like LSR, TPE has similar elasticity, but the elastomeric behavior differs because of cross-linking properties–where the polymer chains are chemically joined together in places by covalent bonds(which LSR has). The result of avoiding the cross-link, it achieves faster cycle times and makes for a cost-saving process. TPE material has outstanding chemical resistance properties, just not at high or low temperatures. TPE can also be formulated to be non-tacky, which helps repel dirt and other contaminants. Additional advantages include:

- Abrasion resistance

- High elasticity

- High fatigue resistance

- High impact strength

- Low density

- Resilient to chemicals and weathering

- Strong and flexible at room temperature

- Suitable for high-volume injection molding

- Resistance to low and high temperatures( -30–140 degrees C)

When Using TPE, hundreds of remolding opportunities appear because there is no chemical change within the material. The only drawbacks of using TPE is how it melts when exposed to high temperatures—which could be considered a positive in some cases—and how it deforms under sustained pressure. LSR can deal with extreme range of temperatures(up to 400 degrees C) and will remain stable. LSR has a high chemical resistance to solvents, oils, and other chemicals, which is ideal for gaskets and O-rings that come into contact with various solvents in the automobile industry.

TPE For Plastic Injection Mold Manufacturing in the Pet Toy Industry

Selecting toys for dogs that are durable, stylish, and sustainably made is a hard task. Manufacturing dog toys can be difficult when considering how to improve the quality and durability of a product. High-quality TPE material is flexible enough for a wide array of uses, including, manufacturing strong, safe, rubbery plastic dog toys that are squishy, fun to play with, and easy to clean. Chew toys especially need to withstand constant gnawing and attempts of destruction. TPE makes for a lightweight, UV light, and chemical resistant toy. They’re safe for the animal to use and are easily molded to offer a variety of textures and colors necessary to keep the animal’s interest. At TechTank, we ensure our customers that we only produce non-toxic, high-quality, and long-lasting toys from superior TPE material.

Using TPE in the Plastic Injection Molding Process for Consumer Goods

Several objects in today’s homes contain thermoplastic elastomers. From handles on spoons and spatulas that are used to flip, stir, and whisk food to the toothbrushes, hair combs, and scissors used for beauty and hygiene care–thermoplastics are everywhere. Thermoplastics are an ideal solution for household products because they are heat and cold resistant. Thermoplastics are some of the most widely used soft plastic materials used in the market. Found in thousands upon thousands of products, manufacturers around the world have recognized this material for its use in consumer applications.

TechTank’s TPE Plastic Injection Mold Manufacturing Capabilities

TechTank’s plastic injection molding services are suited for a vast array of thermoplastics including engineered resins, elastomers, and polyolefins as well as custom color matching. Injection molding is a versatile process, and TechTank has the abilities to handle a wide range of materials such a thermoplastic Elastomers(TPE), allowing us to manufacture high-quality products more efficiently, while also keeping them low-priced for our customers. At TechTank, we provide our customers with numerous value-added options that come after the injection molding process. These services include:

- Assembly

- Packaging

- Fulfillment

At TechTank, our accommodating business model allows instant access to all of our capabilities to provide fast turnaround time for your short-medium run. Find out more about how TechTank is a leader in providing quick, high quality manufactured products for automotive, manufacturing, and commercial applications.

Get a plastic injection molding quote today!

get a quote

by

Brock Allen

|

December 4, 2018

|

Blog

Plastic Injection Mold Manufacturing becomes more Sustainable with Natural Additives

While there are various methods to manufacture plastic products, plastic injection molding is one of the primary approaches many companies choose to adopt. We often hear about the many negative aspects of plastic, from pollution to worries about the non-biodegradable nature of the material. Although this has gained a significant amount of press coverage in recent times, the fact is that due to its desirable characteristics, plastic remains a necessary material to us. Companies like TechTank have been implementing and improvising the use of natural substances into their plastic injection molding process to combat some of the negative realities of using plastic for certain products or components. Currently, TechTank injects natural elements like:

TechTank adds a portion of natural elements along with the plastic material into the injection molding machine to then produce bioplastic products. Adding in these natural additives will help to reduce the enormous carbon footprint that most plastic manufacturing companies have placed throughout the world. Depending on how much clients want to add, TechTank can reduce the amount of plastic up to 50% through this natural additive process.

Why Algae over other Natural Additives & BPA Substitutes?

Algae has a better demand in terms of producing bioplastics as compared to corn, starch, etc. due to food spikes, both through consumption or volatile pricing. Algae has less impact on the food chain and on any food that could be consumed by humans. Also, TechTank believes that algae helps the greening process of plastics and ensure sustainability. A key advantage of using algae over other BPA substitutes is its availability: it is washing up on beaches everywhere and floating in seas throughout the world. The algae-based biomass behaves like traditional starch-based resins and also has a high heat tolerance. In the past, algae plastic had a strong fishy smell, but innovations and new technologically that TechTank has acquired now has a process that eliminates that fishy odor.

This new additive substance has a tall order: people are looking for something can clean up industrial wastewater and polluted fish farms, convert CO2 emissions from utility and ethanol plants into oxygen, and replace fossil fuels — a tall order for pond scum. However, the emerging algae industry is targeting all of them. Green algae, usually found in fresh water, can be used to purify wastewater and remove CO2. Uses of algae help to minimize the carbon dioxide and nitrous gases from polluting smoke-stack environments, and also with potential chemical conversion companies that could convert the algae biomass into viable monomers for further conversion into potential biopolymers. Commercial algae resins represent a significant breakthrough in the greening of the plastics industry, a transformation that we believe is critical to helping ensure the long-term sustainability of the planet.

As the demand for algal biomass increases, the incentives for other industrial plants to build out algae-based water treatment systems and sell the biomass will soon be realized. Livestock operations such as dairies, fisheries, etc. located in the southeast and southwest can use algae to treat their manure effluents and provide additional biomass to the market. Over time the aquatic biomass will become a commodity product traded like other traditional crops. Currently, large amounts of corn are being diverted from food production to enter biofuel or bioplastic production. Introducing a new, low-Eco footprint biofeedstock will help alleviate the demand on food-based crops for plastics and liquid fuel conversion.

The Benefits of Using Bioplastics

Generally speaking, the most considerable advantages of using bioplastics is to reduce the energy footprint and provide a less polluted ecosystem. In theory, the problem of overflowing landfills and floating islands of trash will be addressed through the increased use of bioplastics. Not all bioplastics degrade in a meaningful time span though – it is entirely realistic that some bio-based plastics will remain intact for decades — especially if they are not discarded properly.

Bioplastics are also gaining popularity because they don’t contain bisphenol. Bisphenol S (BPS) are chemicals that were implemented when the FDA put BPA-free regulations on products in the food storage and baby feeding/accessory industries. Bisphenol and other BPA substitutes were not well studied before mass use; however, in the past few years, they have been shown to have endocrine disrupting similar effects to BPA in laboratory tests according to Center4Research. BPA alternatives also enter the human body just as quickly as BPA, suggesting that substituting BPA with new compounds are unlikely to provide any health benefits — showing why it is important to test the safety of potential BPA substitutes before they can be sold. For the time being, most of the concern seems to be centered on BPA’s alleged ability to disrupt hormonal activity. Bioplastics provide a potential alternative to this issue, although there is no guarantee that BPA won’t be added to bioplastics in the future.

The best-understood advantage of biodegradable bioplastics lies in the reduction of permanent litter. Plastic single-use shopping bags are the most obvious example of how plastics can pollute the environment with vast and unsightly persistence. A large fraction of the litter in our oceans is of disposable plastic bags. Cities and countries around the world are taking action against these type of bags, sometimes by banning non-degradable plastic bags entirely.

Are there Disadvantages to Using Bioplastics?

It can be challenging for consumers to determine if the conventional plastics they’re using are biodegradable, compostable, or otherwise recyclable. For this reason, many bioplastics do not get recycled. Many facilities don’t have the abilities to sort, compost, or recycle bioplastics; so everything ends up in a landfill anyway. For example, a cup made from polylactic acid (PLA) looks and feels like regular plastic, so a consumer may throw it into the recycle bin when it could be composted.

Aside from identifying bioplastics correctly, they must be discarded appropriately to biodegrade or compost. For instance, if a biodegradable fork is packed into an airtight landfill, it may not degrade at all. Conversely, anaerobic degradation–decomposition, in the absence of oxygen, could happen when moisture is present. Meaning biodegradable bioplastics create an air pollution problem.

Other companies already use starches from corn, tapioca, wheat, and potatoes in manufacturing hybrid plastic products. Many competitors question why would TechTank bother adding yet another biomass to the mix? Simple. Algae is cheap, plentiful, doesn’t take away from the human food chain, and represents the near-perfect closing of the renewable products loop.

TechTank–Your Natural Plastic Injection Mold Manufacturer

TechTank can provide natural, environmentally friendly plastic injection molding services on full-sized runs, but mainly works with small to medium sized runs (around 5,000 pieces). TechTank offers a vast range of plastic injection molding services, working with all thermoplastic materials such as PETG and polyurethane. TechTank performs contract plastic injection molding services for many industries including medical and retail.

TechTank does more than plastic injection molding and CNC machining. TechTank provides in-house new product design, development, prototyping, and manufacturing for various products across hundreds of industries. TechTank has the resources needed to take a new product idea from a concept and turn it into a reality, manufacturing high-quality products with quick turnarounds. Unlike your average machine shop, TechTank’s mission is to provide our customers with the best possible products inexpensively. For more information on the advantages of using natural additives in the plastic injection molding process with TechTank, contact one of TechTank’s professionals today.

by

Brock Allen

|

September 4, 2018

|

Blog

Plastic Injection Molding Is:

- A process that produces large numbers of high-quality parts with great accuracy, very quickly

- Provides low labor costs by working hand-in-hand with prototypes

- Has the ability to manufacture complex part designs fast & efficiently

- Works with various plastic materials to create a flexible yet durable product

The Plastic Injection Molding Process

Plastic injection molding is a common manufacturing process perfect for creating a unique product and being able to mass-produce the product upon the design. At TechTank, our plastic injection molding manufacturing provides our clients the most reliable, high-quality products available. The plastic injection molding process involves injecting molten plastic into a mold cavity where it then cools and hardens into the end product or part. Injection molding starts with an engineer designing a mold for a specific purpose. That mold design is then turned over to a toolmaker to create the mold usually from either steel or aluminum. This mold is precision machined to form the exact features of any desired widget and then used to inject molten plastic into which then forms the part. 3D printers and CNC machines are often used to prototype the part which can be used as a model to form the mold.

What are the Advantages of Plastic Injection Molding?

There are three main advantages when discussing plastic injection molding over other molding processes. The three advantage are:

- Pricing (Cost) of plastic injection molding

- The efficiency of the injection molding process

- The consistency of the injection molding process

Pricing of Plastic Injection Molding

Once the initial design and mold have been completed, the price per unit for plastic injection molding manufacturing end up being quite reasonable. The ability to scale products produces via injection molding is the biggest advantage. With the price per unit almost always dropping as more products are produced, this allows retail clients to make more margin as sales increase.

The Efficiency of the Injection Molding Process

Traditional manufacturing (think CNC machining) often times produces large amounts of scrap or waste while creating a widget. Not only does this add time to the manufacturing process, it also requires more raw material too. Injection Molding greatly reduces the scrap to product ratio and also, especially the case with plastic injection molding, the scrap can be recycled back into production. The little waste that is produced through plastic injection molding is from the leftover plastic left in the spruce, runners, and gate locations upon completion of the mold. There is also a certain amount of leakage from the mold too called flash. Below explains more about those terms:

- A spruce guides molten plastic to the entry point of the mold. This is a separate–usually custom–piece that needs to be designed for each individual mold.

- Runners shoot off the main spruce running the plastic to individual parts. There are both hot and cold runners depending on their purpose in the mold.

- The gates connect from the runners and hold the product to the main assembly. This is the final point of the molten plastic before entering the cavity.

- There is also a certain amount of plastic that leaks out of the injection mold cavity while filling it-a condition called flash. Flash is a molding defect where the plastic oozes usually through the parting line or ejector pin locations. When the excess plastic cools, it remains attached to the widget requiring additional work to finish the product. This can sometimes be remedied through increasing clamp pressure or regular maintenance of the mold itself.

The Consistency of the Injection Molding Process

This may go without saying, but there are considerable pros to producing a product that is exactly identical every time. Whether it be for branding or interchangeable parts, consistency has its advantages. This plays off the pricing point too where large quantities of a widget can be produced to be used as a future component at a very low relative cost. Having a consistent product every time allows for this kind of cost-saving. Though if designs change, this could negatively affect efficiency if there are outdated parts laying around. The good news is almost always the raw material can be recycled and formed into a part that is now needed.

Things to Consider for Injection Molding Applications

Working with TechTank can help tackle many of the pitfalls to plastic injection molding and help consult whether or not the application is suitable for this manufacturing process. Many products are produced through plastic injection molding; everything from bottle caps to automotive dashboards to shopping carts are created using injection molding. Simply put, plastic injection molding is one of the most common methods of part manufacturing, but there are many parameters which injection molding needs to operate within. Below are aspects of the plastic injection molding process to consider when designing a particular product or part. TechTank is happy to help anyone interested in producing a product and is one of the services offered through the Founder’s Club Program.

Design and Specifications

3D printers are almost always used in the initial prototype development. It is important to consider whether or not a product can be created through 3D printing to create a mold suitable for the application of the end-product or part. Another design specification to consider is not only designing the product itself, but also the injection mold tool (spruce, runners, gates, etc.). The mold tool carries the molten plastic to the cavity to create the widget. Generating anything over 300 prototypes will generally require the development of the plastic injection molding tool for production.

Another potentially time-consuming process is the trial and error required on both the injection molding tool and the cavity for the end-product to refine any details before mass-production. This is where economies of scale and consistency will hurt if 10,000 identically defective widgets are produced on the first mass-produced run. Take the time to create many prototypes first to avoid this pitfall.

Tooling for Injection Molding

High tooling costs for injection molding can be a drawback as this is an entire project in and of itself before any thought to a mold can even be placed. Extensive testing is required, and because most tools are made out of steel or aluminum, making changes can be difficult.

Keep in mind material can always be added to a mold by making the cavity larger by cutting away the metal or aluminum. But taking away plastic (reducing the size of the cavity) is a much more difficult task oftentimes requiring an entirely new tool to be produced. Starting over is where cost can become a significant factor. In some cases, welding in additional metal or aluminum to the cast is possible, but this is highly-skilled and time-consuming work.

Wall Thickness & Size Limitations

In the perfect injection molding world, the thickness of each wall within the mold would be exactly uniform. If the walls are too thick, sinkholes and other inconsistencies are more common when the plastic is cooling. Having walls too thin, however, can create gaps in the product because the entire mold is not filling properly. Walls around 4 mm thick is a good compromise and also helps to prevent waste by having walls any thicker. Anything thinner than 1 mm will generally cause problems in the injection molding process.

Many products designed by injection molding end up being much larger than the injection molding machine itself. For example, a large plastic crate would need to be assembled in pieces and constructed separately after the injection molding process is complete. And sometimes it’s not so much the capacity of the injection molding machine, but more how large the CNC machine or 3D printer is to produce the prototype or tool in the first place. So large 3D printed parts also need to be printed in multiple parts and put together to create exactly what is needed for injection molding. All things to consider when considering injection molding.

Final Thoughts on Injection Molding

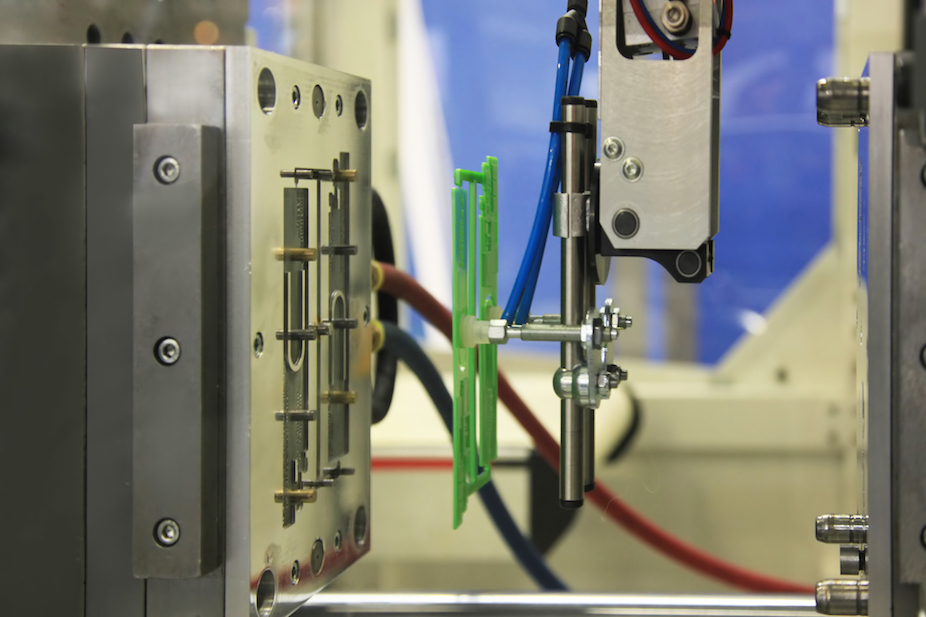

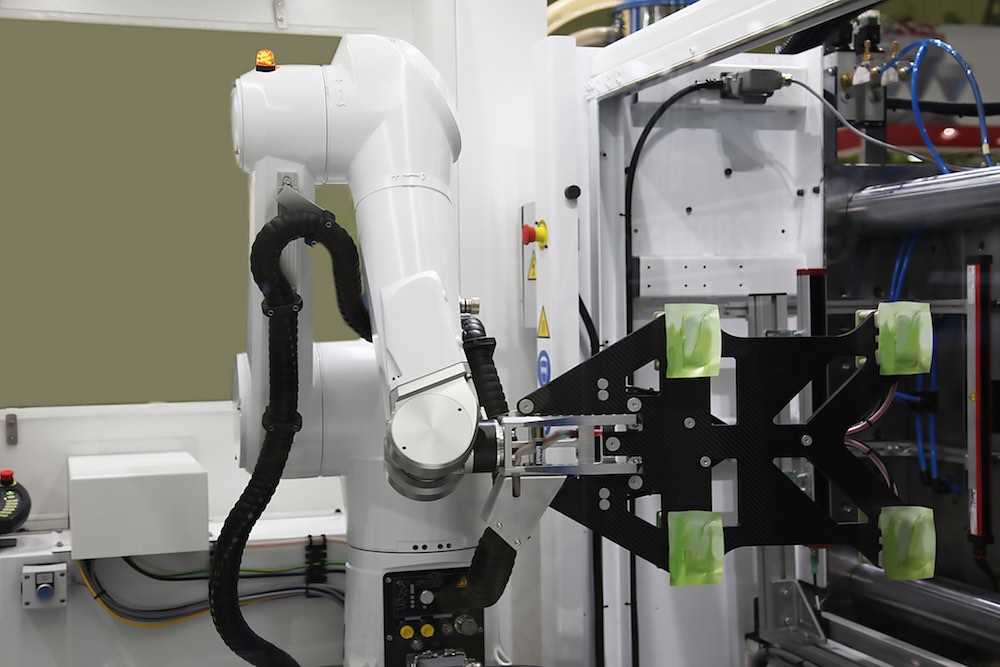

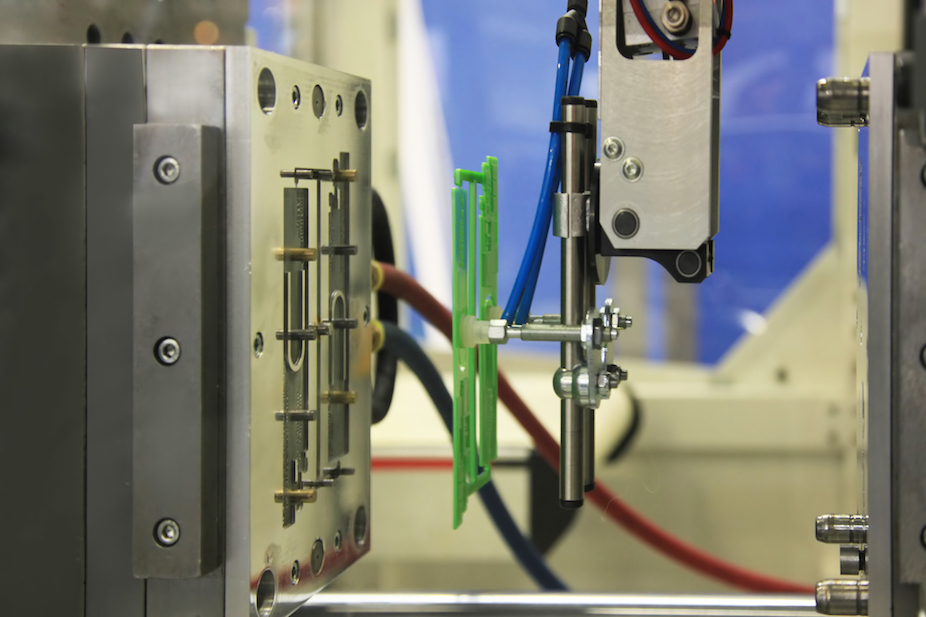

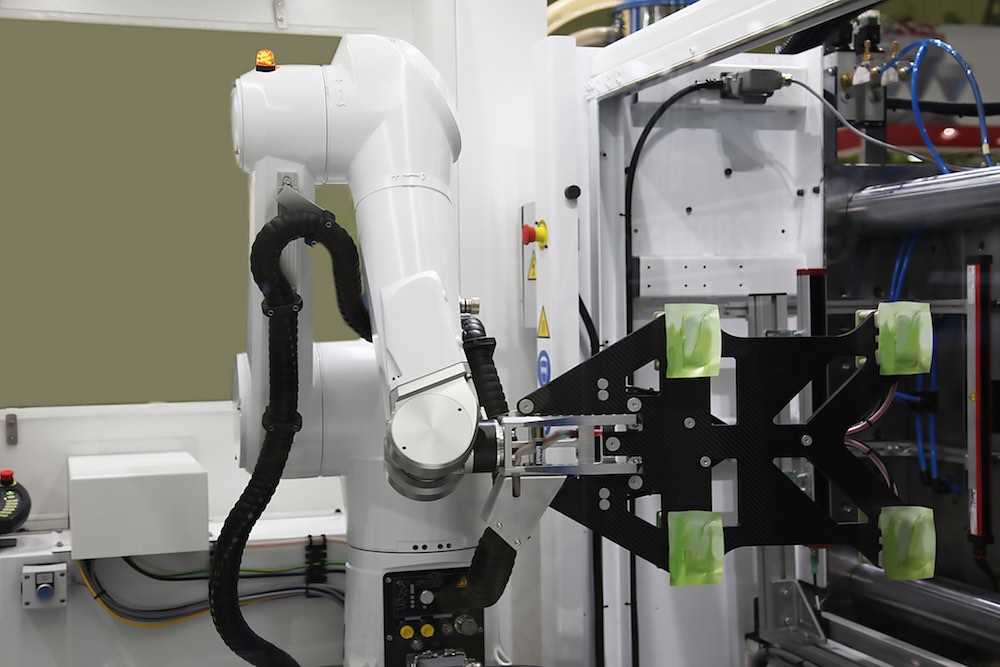

Injection molding is marvelous technology. It allows engineers to design and create many products (or parts of products) in large quantities and thus low prices to the consumer. And though it is not perfect for every design spec ever thought of, a mold can be creatively designed to help overcome problems when designing a product. TechTank has partnered with Live Automation’s advanced collaborative robot technology to help overcome some of the labor issues and competitive pressures that impact plastic injection molding to make the process as easy as possible. Overall, injection molding is widely considered an affordable way to produce high-quality, consistent products on a large scale.

by

Brock Allen

|

August 23, 2018

|

Blog

According to Adobe’s 2018 Digital Intelligence Briefing, only 15% of businesses use some form of artificial intelligence today. However, over the next 12 months, Adobe predicts that 31% of companies to implement it. Companies are implementing robotics into their production lines in order to increase speed and differentiate themselves. This upward trend is foreshadowed to continue, meaning companies in the industrial industry need to stay on top of these trends to be able to compete with the competition.

TechTank has recently begun working with Live Automation to implement collaborative robots for B2B companies in the industrial, automotive, and manufacturing industry. Collaborative robots assist in various processes including injection molding process, CNC machining, and more to provide a competitive edge for producing low-cost, fast, and high-quality products. Aside from selling customers collaborative robots, TechTank offers new product development and in-house services including CNC machining, injection molding, and cybersecurity. From product design to production, TechTank has the resources, staff, and processes to turn your product idea into a finished result.

Eliminate Errors & Reduce Expenses by Using Collaborative Robots

Businesses in the 21st century are highly competitive and falling behind leading competitors die to irreparable disasters. Although collaborative robots have only been commercially available for about a decade, they were actually invented back in the 90’s. Alongside modern industrial automation, terms like ‘Cobot’ are showing up in the web space more than ever. The most obvious benefit of purchasing a collaborative robot for manufacturing processes, aside from offering higher efficiency to industries, is freeing up floor space and lowering the cost of implementing non-collaborative robotics. For example, a non-collaborative robot used in an automated cell must be guarded to keep operators outside. The guarding itself can be expensive, especially when gates, interlocks, and interfacing to the cell controller are included. However, the cost of moving material in and out of the cell is often overlooked. With collaborative robots, the cage is eliminated and an operator can work alongside the robot, positioning the material or workpiece, and removing finished pieces as needed.

Less obviously, collaborative robots permit flexible manufacturing practices. Even when equipped with vision systems, there are limits to a robot’s ability to handle unexpected conditions. Consider a material removal cell where a robot is trimming plastic moldings. Excess material builds around the tool and workpiece and pushes the plastic away from the tool. In a collaborative setup, a human operator can step into the cell and the robot will pause while the buildup is removed. Then, with the operator safely out of the way, production will resume.

Collaborative robots can save space and money and increase flexibility. Live Automation requires all automated machines to meet strict safety guarding and safe operational requirements. Still, it is essential to conduct a formal risk assessment before ditching the cage.

How TechTank Uses Collaborative Robots for Industrial & Commercial Applications

TechTank uses collaborative robots for a wide range of tasks. Unlike standard robots, collaborative robots have numerous abilities, letting TechTank use them for their own custom needs. Collaborative robots perform people-oriented tasks, especially the mindless and tedious ones that do not involve a high amount of skill. Things such as stacking and unstacking heavy boxes, filling and emptying containers, and organizing materials are completed with the use of these collaborative robots. Implementing automated robotics over manually operated equipment eliminates repeated tasks that can result in a human error during any manufacturing process. TeckTank’s team of professionals can now focus on continuously supervising, administering, monitoring, and analyzing all machines and robotics more efficiently instead of working on the tedious actions involved in CNC machining, plastic injection molding, etc.

By replacing manually operated machines for specific tasks, TechTank has been able to create quality products with faster turnaround times. Live Automation’s collaborative robots can run nonstop for several months, reducing idle times and shortening long-term projects. Reducing the time spent on manufacturing services not only results in quicker turnovers, but it allows TechTank to take on more significant projects and manufacture massive quantities at once. Resources and time are no longer wasted, resulting in more revenue, setting TechTank apart from other CNC machining and injection molding companies.

TechTank’s Quality Low-Cost Manufacturing Services

TechTank offers a vast range of plastic injection molding services, working with all thermoplastic materials such as acrylic, PETG, and polyurethane. TechTank performs contract injection molding services for many industries including, industrial, medical, and retail. TechTank focuses on providing inexpensive prototyping to confidently compete with other plastic injection molding and CNC machining companies and their costs across the world.

Some types of injection molding services we offer include:

- Conventional injection molding

- Open/close, slide, and insert molding

- Two-shot/over-molding

- Small tonnage machines ranging from 22-150 ton machines

- Prototype services with 3D printing

- 3D printed prototype molds

- MUD frame inserts

- Overflow manufacturing

- Mold studies and tool analysis

Some CNC machining services we offer include:

- Electrical Discharge Machining

- Milling

- Grinding

- CNC Lathe

- Milling

- Grinding

- CNC Lathe

TechTank has the ability to provide all plastic injection molding services on full-sized runs but mainly works with small to medium sized runs(around 5,000 pieces). At TechTank, we do more than plastic injection molding and CNC machining. TechTank provides in-house new product design, development, prototyping, and manufacturing for various products across hundreds of industries. TechTank has the resources needed to take a new product idea from a concept and turn it into a reality, manufacturing high-quality products with quick turnarounds. Unlike your average machine shop, TechTank’s mission is to provide our customers with the best possible products inexpensively. For more information on the advantages of buying collaborative robots with TechTank, contact one of TechTank’s professionals today!

Recent Comments